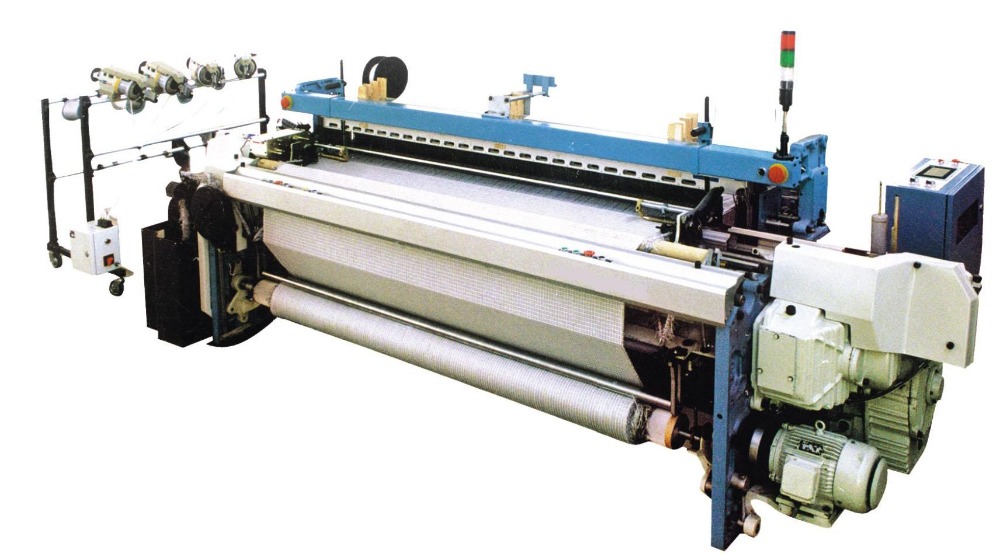

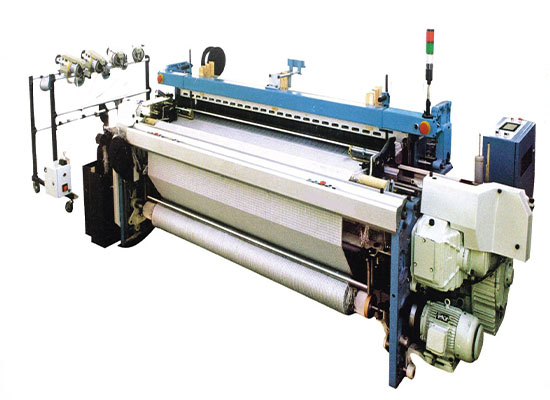

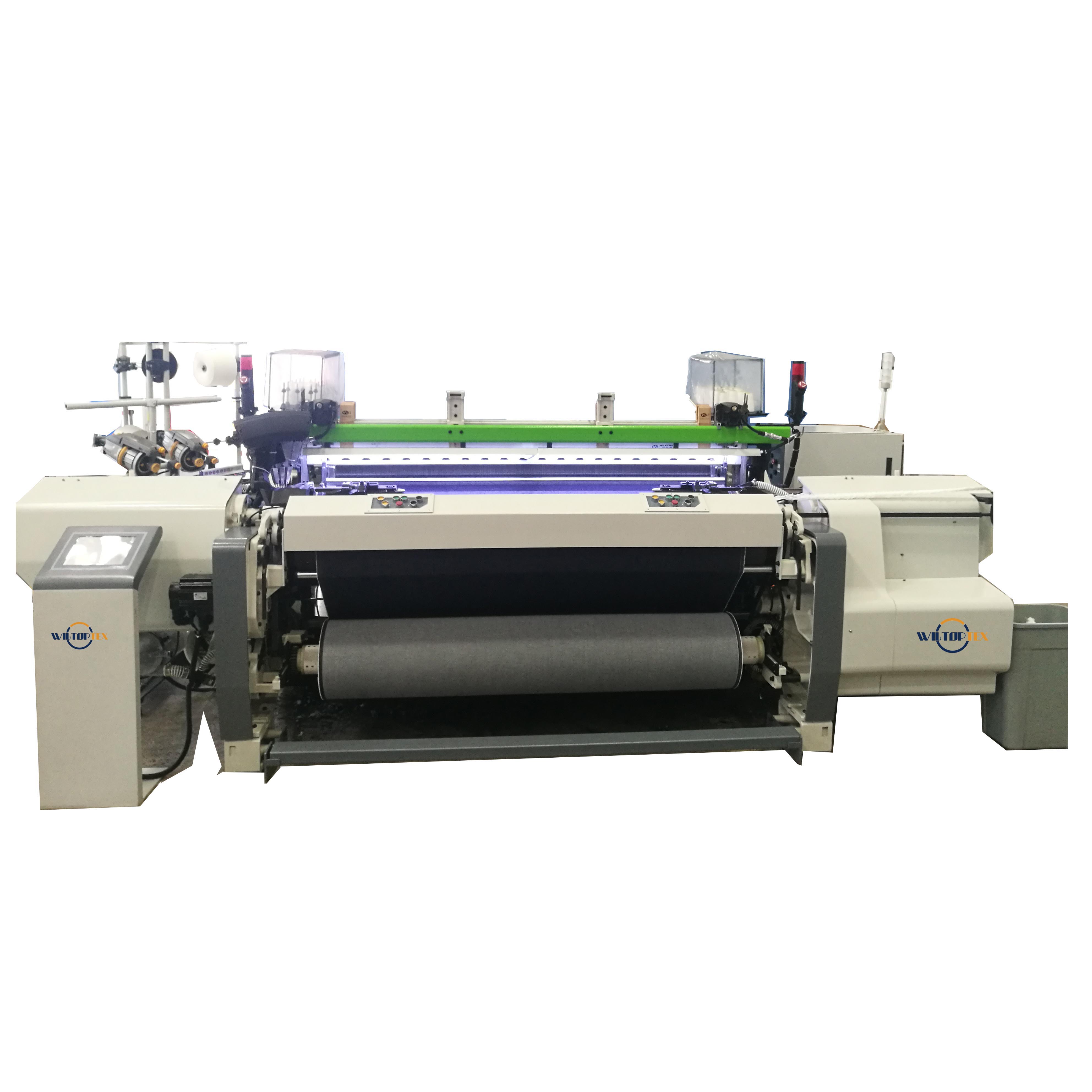

HYRL-1724 Rapier Loom is designed and manufactured to meet the requirements of the weaving industry on the basis of the SM-93. It is more flexible and applicable .

This loom adopts rotary electronic dobby , fully electronic let-off and take-up system , suspension guide hook . Perfect electronic control, menu-type program, and practical memory card. During the weaving it allows to have as many as 8 weft densities,and accordingly 8 settings of tension. For the special loom and necktie jacquard loom it is possible even to set a warping-stop function,so this loom is much more versatile and flexible in use.

Technical parameter

Main specification:

Reed width | 190cm | 210cm | 230cm | 280cm | 360cm |

Max. weft inseration rate (m/min) | 530-685 | 588-714 | 644-782 | 650-875 | 750-1008 |

Speed (rpm) | 300-350 | 300-350 | 300-330 | 270-300 | 250-320 |

Yarn range | Cotton6NE—80NE,wool 10Nm—135Nm,chemical fiber 900D—70D | ||||

Shedding | Mechanical dobby or electronical dobby | ||||

Weft insertion form | Separate reeds positively driven by conjugate cams at both ends | ||||

Beating-up motion | Separate sley bars positively driven by close conjugate cams at both ends | ||||

Let-off motion | Contionous let-out of warp by compound regulating system | ||||

Take-up | Positive continuous take-up motion with weft density regulators | ||||

Weft selection | Electrical color choosing device; max.8 weft colors. | ||||

Diameter of warp beam | 800 mm or 1000mm | ||||

Warp stop | 6 rows electric warp stop | ||||

Weft stop | With piezoelectric sensor control weft stop | ||||

Power consumption | 4.8KW | ||||

We can manufacture according to customer's requirements