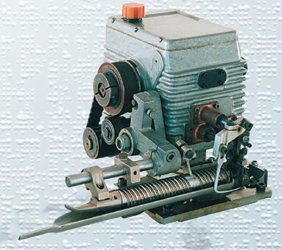

HYRL-727 is used to weave fabric with crude fibers (cotton, wool, hemp), chemical fiber and blending yarn etc. It is better for weaving thick fabrics than HYRL-717 model loom.

With stronger frames and improvement of the beating-up and weft insertion devices on HYRL-717, HYRL-727 is specially designed for weaving thick fabrics and the speed higher than HYRL-717 loom.

1.Adopt the four-links short crank shorten and strengthen the lay swords, that get the loom to produce stronger strength when it beating up and the speed is higher.

2.The new six-links weft insertion system replaces the old four-links weft insertion system, that assures the rapiers head have enough time to finish weft transfer inserting and get handover to be stable

Technical parameter

Reed width(cm) | 180 200 230 280 330 340 360 |

Speed R.P.M | 180---230 |

Yarn range | cotton 6Ne~80Ne, wool 10Nm~135Nm, chemical fiber 900D~70D |

Shedding | Upper mechanical (electronic) dobby, spring reversing motion, and 20 or 24 shafts |

Weft insertion form | Six links weft insertion |

Beating-up motion | Four links short crank arm beating-UP |

Let-off motion | Adopting friction type let off |

Take-up and rolling-up | Continuous take-up and separate rolling-up, full rolling diameter 400mm |

Weft selection: | 4~6colors( mechanic or electronic ) |

Diameter of warp beam | Φ600mm Φ800mm |

Warp stop | 6 rows electric warp stop |

Weft stop | Piezoelectric ceramic sensor weft stop |

Electric system | P.L.C |

Power | 1.8~2.2kw |

Weight: | 2200~2500KG |

Overall size | 3700×2000×1800mm (200cm) |

*** the automatic pick finding device can automatically excute the reversion of shed to weft breakage.making the warp let-off and take-up motion retreat via driving shaft thus reducing the weft crack and crammedmarks due to breakage. it can also improve the quality of fabric surface and easy to operation.