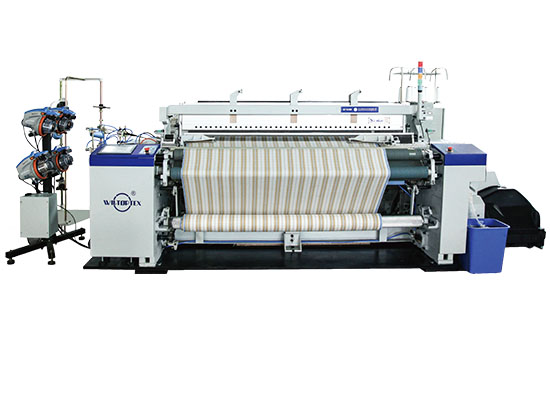

Using new weft insertion system , energy saving main nozzle and one by two sup nozzle , we can realize high speed weft insertion under low pressure, better weft insertion time control and energy saving.

·With the help of new electronic control system ,the automatic setting of weaving process parameters and monitoring of operation state can be realized.

Technical parameter

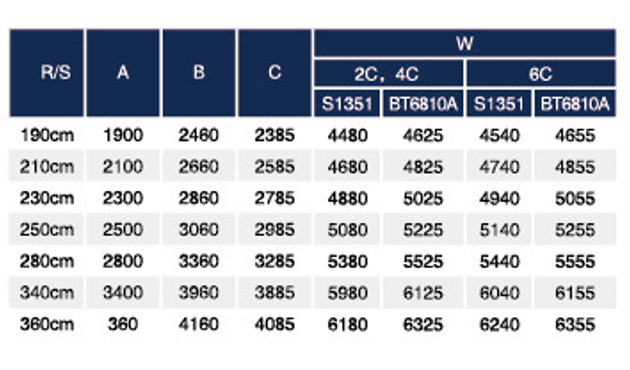

Item | Specification | |

Reed space(cm) | nominal | 190 210 230 250 280 330 |

Useful reeding width | Same as nominals width maximum reduction 80cm | |

yarn range | Spun:Ne100-Ne5 | |

Welf section | 2-colour mixing ,2 colour at-will,4 colours,6 colours | |

| Direct start of rush-start motor drive ,push-third operation with both hands | |

Motor power | 2.7KW,3.OKW,3.7KW | |

Weft Insertion | Main and sub-nozzles combined system,profile reed,auxiliary main nozzle | |

Shedding | Crank plain shedding:shaft number 4 | |

Let-off | Electronic let-off with kickback function | |

Flange dia | 800cm | |

| ETM electronical take-up | |

MTU mechanical take-up | ||

Max.take-up Dia | 400cm | |

Pick density | 6.6-80.5 picks/cm(16.7-204.4 picks/inch) | |

Length count | i-board display,take the function of fixe measure stop | |

temple | Floor-mounted | |

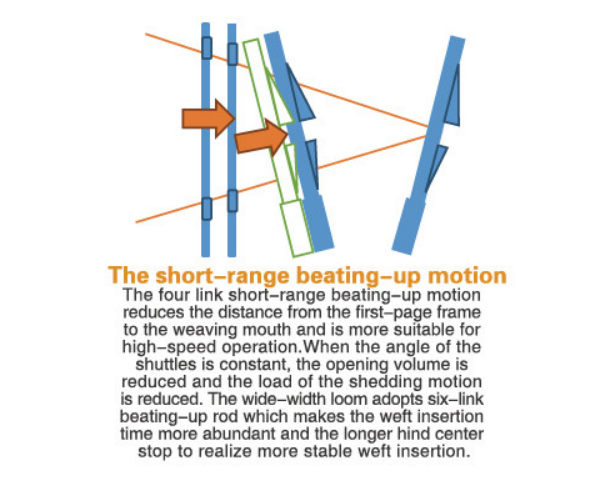

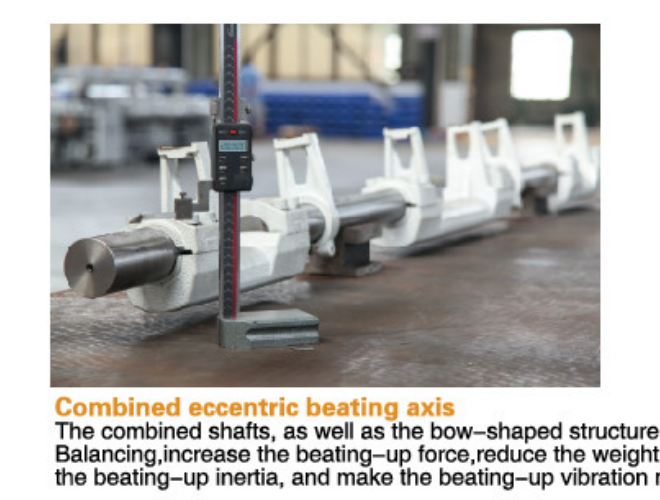

| Crank type beating ,multiple sley sword beating | |

Measuring /storing | FDP Free Drum Pooling | |

Filling supply stand | Floor-mounted for 4 packages(2 colours), Floor-mounted for 8 packages(4 colours), | |

Selvedge | Planetary gear motion | |

Waste filling removal | Catch cord type(gear type) | |

Cutter | Mechanical cutter | |

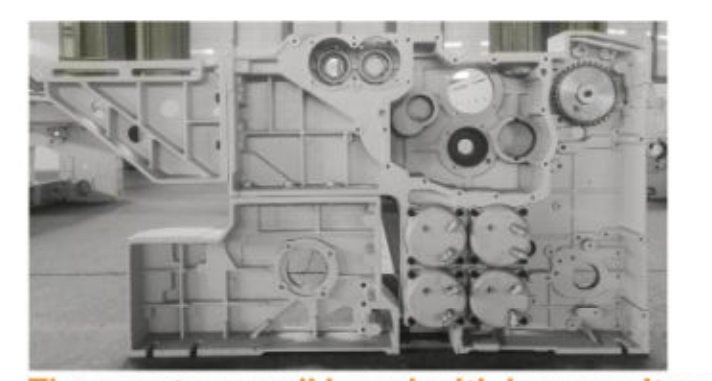

lubrication | Oil bath system for main drive parts, centralized lubrication(manual grease) | |

| Catch yarn | Reflective weft feeler(single feeler) |

others | Stop motion for selvage and catch cord yarn | |

Stop cause indication | Message on I-bord, 4 colour lamp for indicating cause | |

| Wih I-boar (datasetting,automatic control ,monitoring, self-diagnosis function) | |