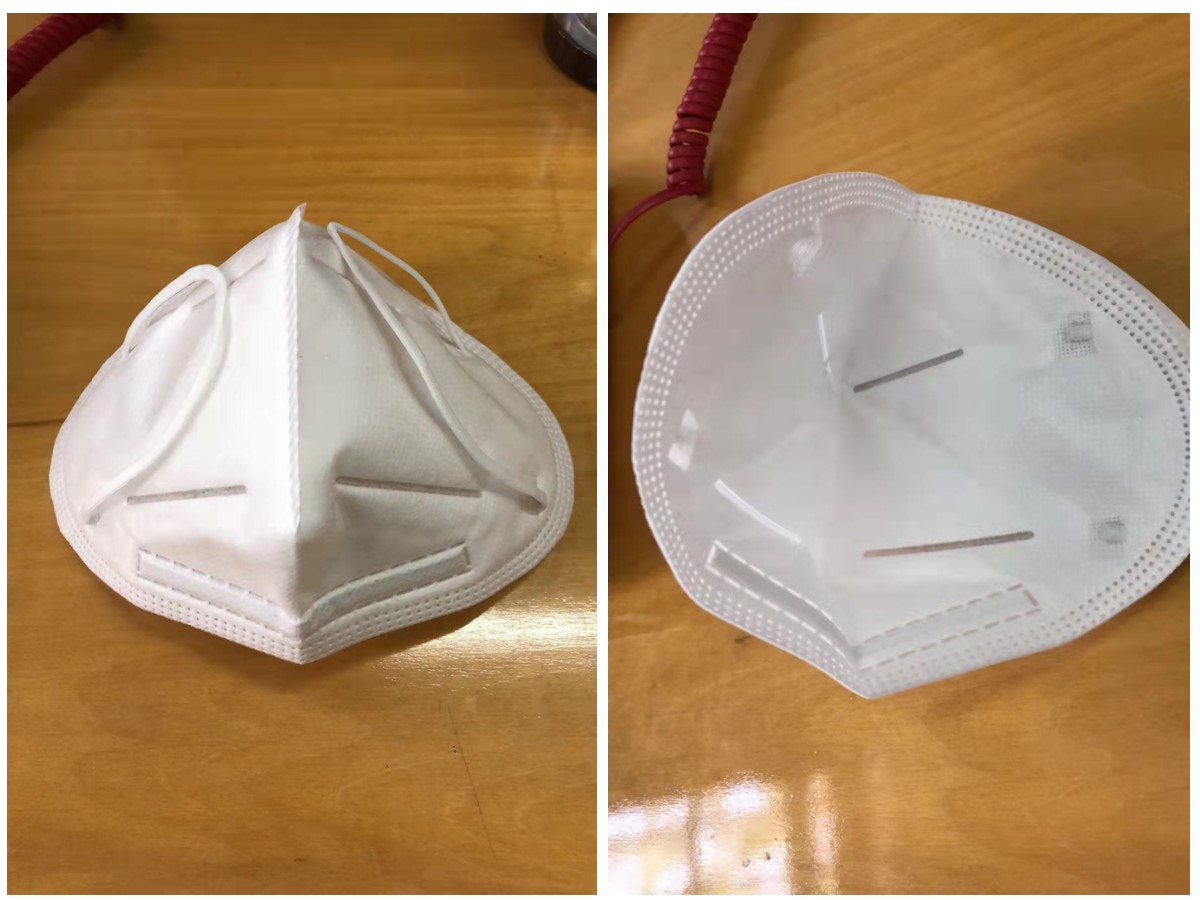

JWN3011 Automatic N95 Duck-billed Folding Face mask Machine is an efficient mask production line equipment.

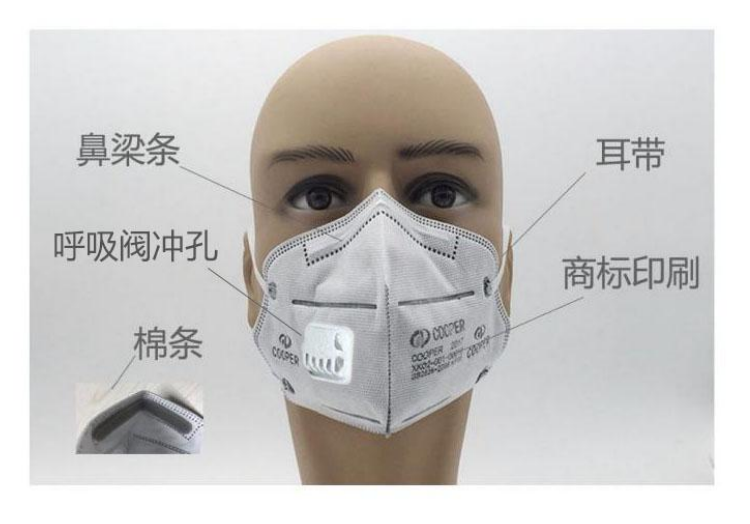

It realizes the whole automatic production process from non-woven cloth raw materials into finished masks. It mainly consists of five parts: raw material bracket, welding and pressing, ear band welding, folding & welding and shaping by rolling cut. Trademark printing, breather valve punching and nose bridge sticking cotton (labeling machine) are optional. The whole processes are controlled automatically for producing N95 Duckbill folding mask.

The machine, controlled by PLC, adopts the latest ultrasonic welding technology with advanced technology, rational structure, reliable operation, convenient operation.

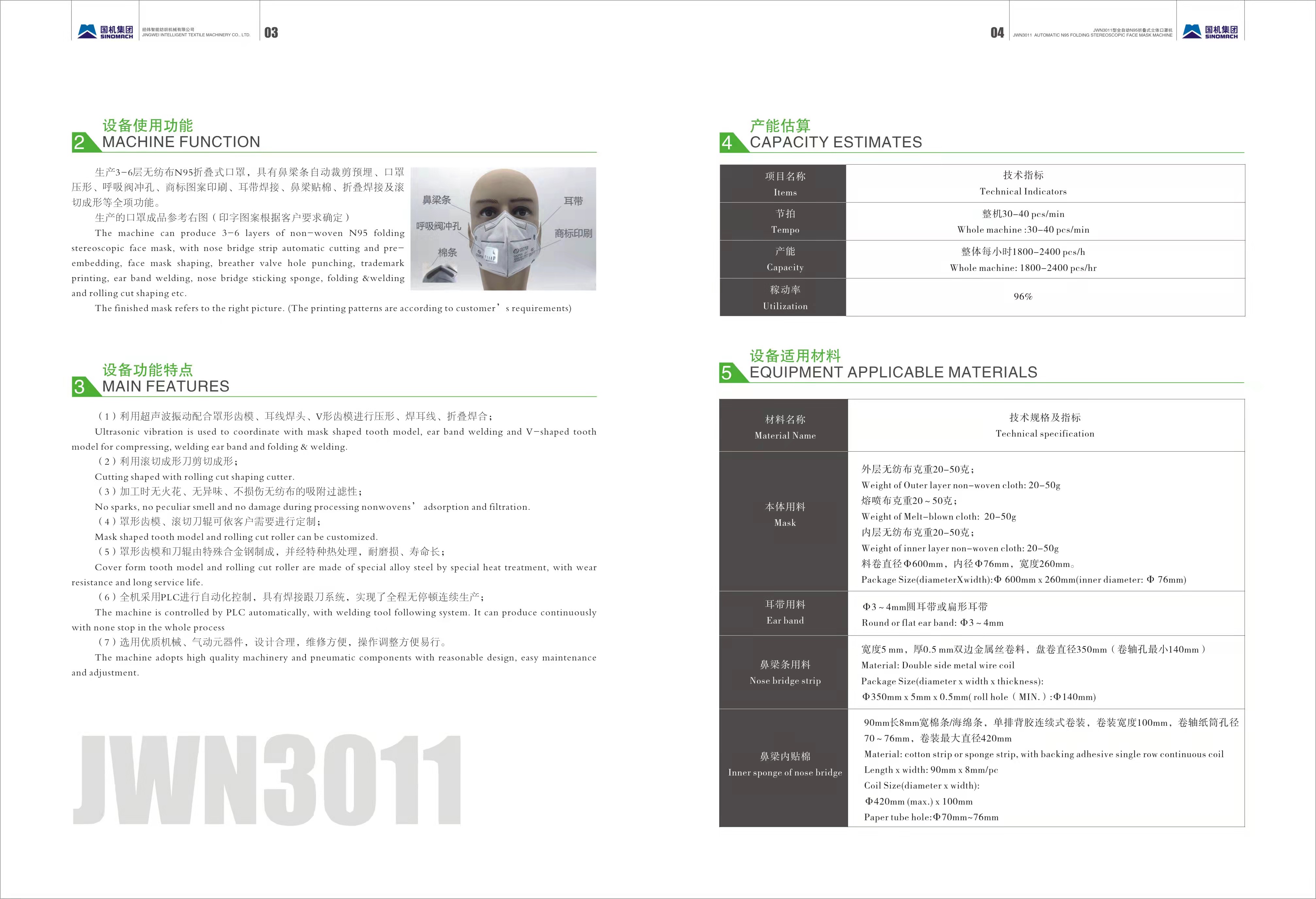

Technical parameter

Automatic N95 Duck-billed Folding Face mask Machine

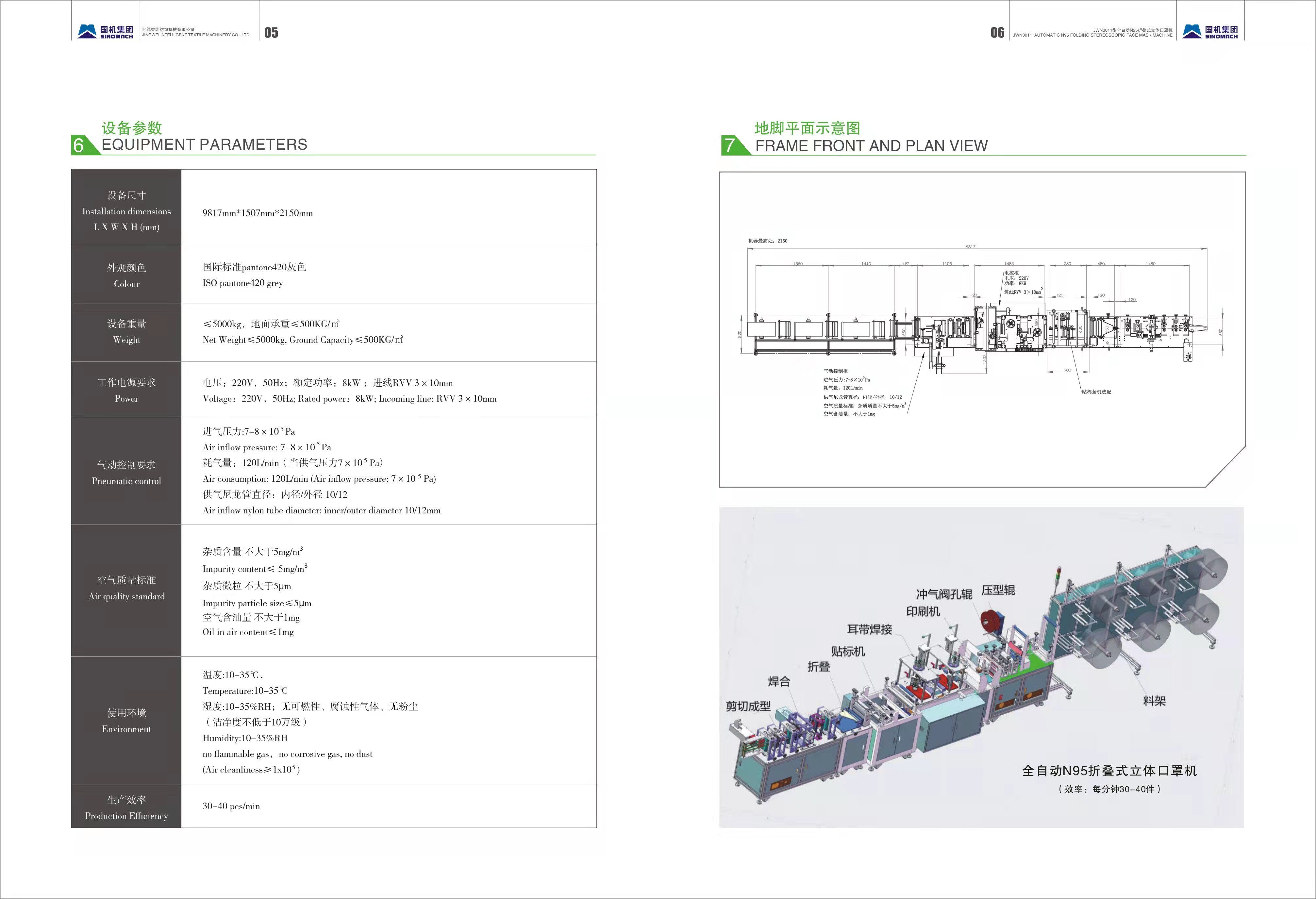

Cutting shaped![]() welding and seaming

welding and seaming ![]() Folding

Folding ![]() Labeling Machine

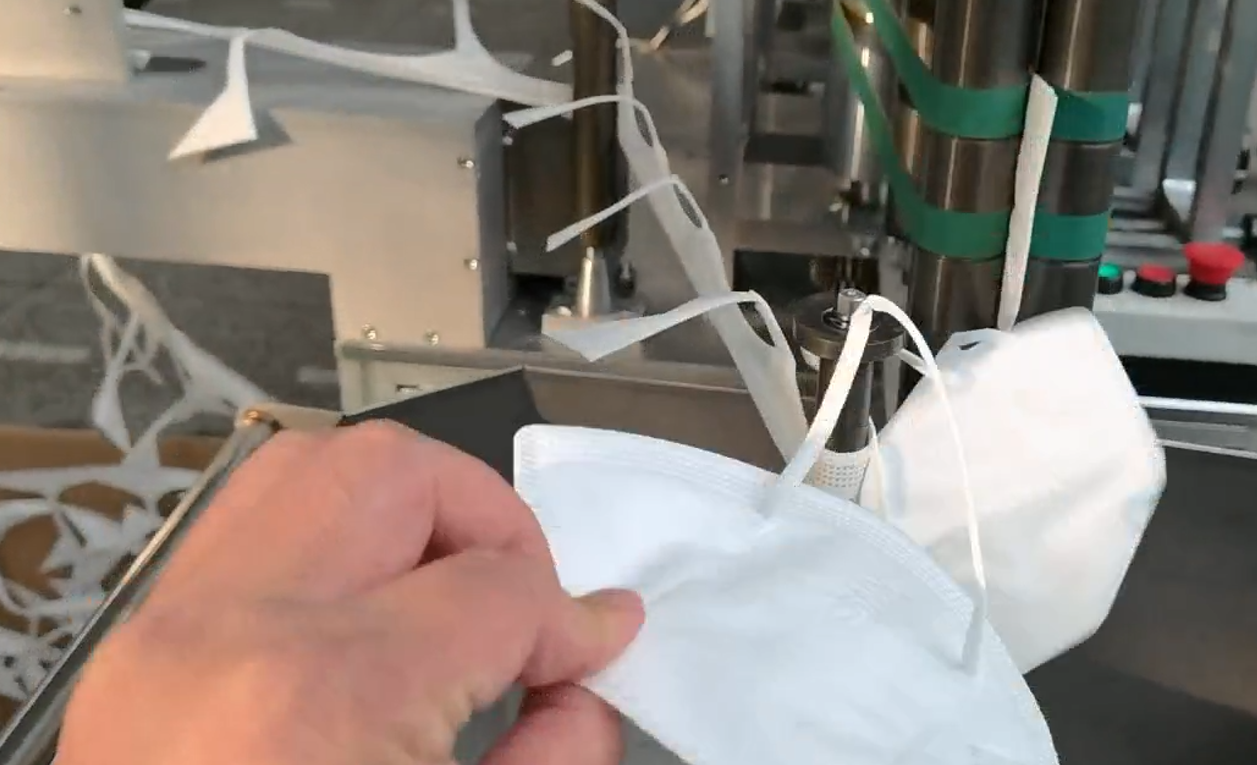

Labeling Machine![]() Ear band welding

Ear band welding ![]() Painting Machine

Painting Machine ![]() Breather valve hole punching roller

Breather valve hole punching roller ![]() Pressing roller

Pressing roller ![]() Raw materials bracket

Raw materials bracket

Painting Machine, breath valve hole punching and nose bridge-sticking sponge (labeling machine) are optional.

Material Name | Technical specification |

| Mask | Weight of Outer layer non-woven cloth: 20-50g Weight ofMelt-blown cloth: 20-50g Weight of inner layer non-woven cloth: 20-50g Package Size(diameterXwidth):Φ 600mm x 260mm (inner diameter: Φ 76mm) |

| Ear band | Round or flat ear band: Φ3~4mm |

Nose bridge strip | Material: Double side metal wire coil Package Size(diameter x width x thickness): Φ350mm x 5mm x 0.5mm( roll hole (MIN.):Φ140mm) |

Inner sponge of nose bridge | Material: cotton strip or sponge strip, with backing Length x width: 90mm x 8mm/pc Coil Size(diameter x width): Φ420mm (max.) x 100mm |